For 110 years, all processing stages of our products have been carried out in Calabria. We firmly line up against relocation, in order to guarantee our Made in Italy quality.

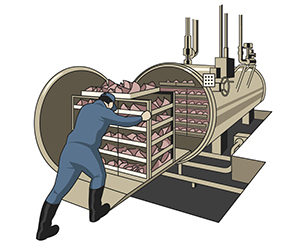

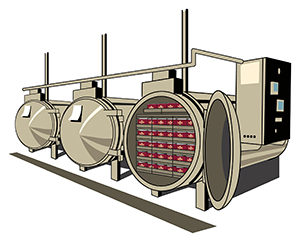

Actually, the secret of our quality is processing, as the result of a balanced combination between tradition, technology and a special care for the entire productive process,

from the raw material selection to products maturation up to marketing.